We Blow-Fill-Seal for you: Contract filling and development

CDMO is your fastest and easiest way to access BFS technology. It's particularly economical for test fillings, market batches or very small series. No matter what the industry, liquid or semi-solid, we support you from the initial idea through design to contract filling and packaging at the highest standards.

CDMO lässt

keine Wünsche offen.

Lohnabfüllung und -verpackung

Über 50 Anlagen. Mehr als 2 Millionen BFS-Packmittel von 0,04 ml bis 10 l täglich. Zu 100 % aseptisch.

Analytik und Prozessentwicklung

Unser Wissen schafft Ihnen effiziente und rundum sichere BFS-Prozesse. Zudem unterstützen wir Sie bei der Produktentwicklung.

Packmittelentwicklung und -design

Die für Sie beste Lösung aus über 100 frei verfügbaren Behälterformen oder ihr individuelles Design. Dazu verschiedene Kunststoffe und eine attraktive Umverpackung.

CDMO lässt keine Wünsche offen.

Good Manufacturing Practice

Stetige Kontrollen und lückenlose Dokumentation gewährleisten Ihnen höchste Qualität und halten Ihnen den Rücken frei.

Pharma-Suite-Service

Auf Wunsch nehmen wir Ihre bottelpack-Anlage bei uns in Betrieb und fertigen in Ihrem Auftrag.

Zulassungs- und Registrierungshilfe

Zum Beispiel in Form von Extractables und Leachables Studien, analytischer Daten oder Vorlagendokumenten für Qualifizierung und Validierung.

CDMO leaves

nothing to be desired.

Contract filling and packaging

Over 50 bottelpack machines. More than 2 million BFS packaging containers from 0.04 ml to 10 l daily. 100% aseptic.

Analytics and process development

Our knowledge creates efficient and all-around secure BFS processes for you. In addition, we support you in product development.

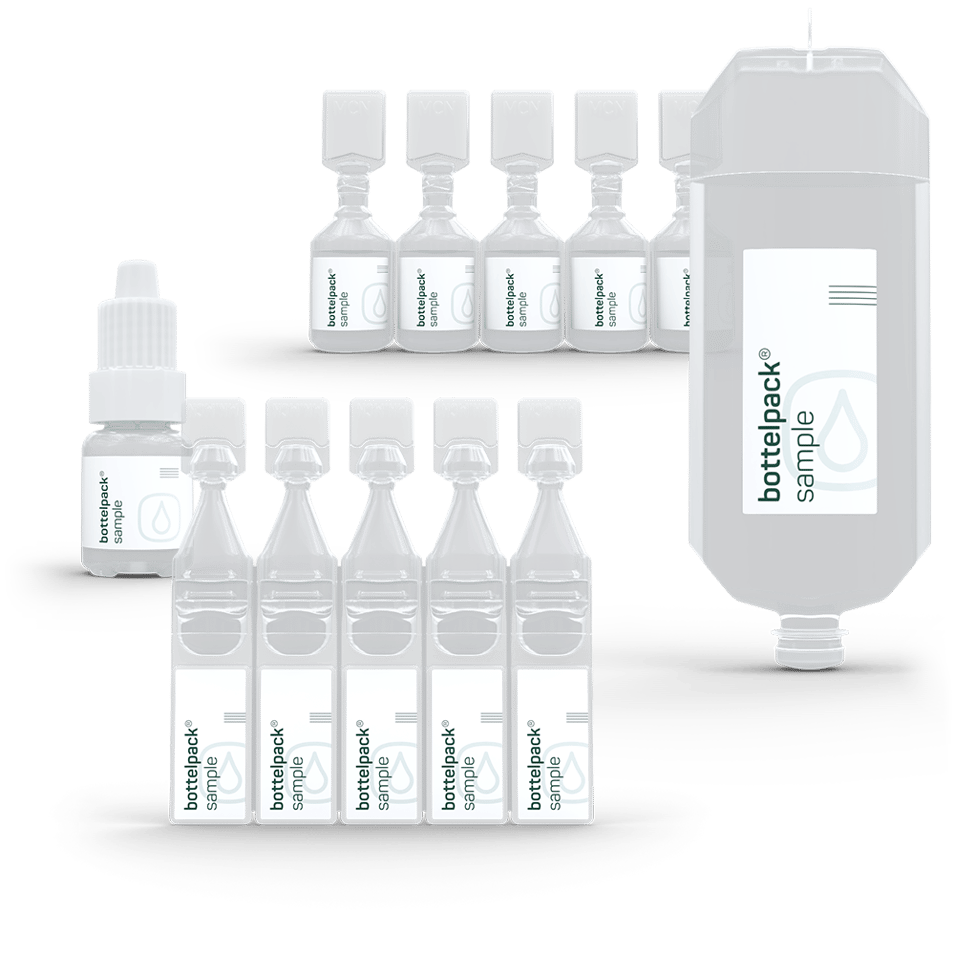

Packaging development and design

The best solution for you from over 100 freely available container shapes or your individual design. In addition, various plastics and attractive outer packaging.

CDMO leaves nothing to be desired.

Good Manufacturing Practice

Constant controls and complete documentation guarantee you the highest quality and keep your back free.

Pharma Suite Service

We can commission your bottelpack machine and manufacture on your behalf if you wish.

Admission and registration assistance

For example, extractables and leachables studies, analytical data, or template documents for qualification and validation.

Contract filling? Worth it!

Blow-Fill-Seal is the most economical way to get your liquids or semi-solids into the perfect shape. But investing in your own equipment doesn't always pay off. For these cases, there is our CDMO service. This means that you have a complete GMP infrastructure, bottelpack technology in various configurations, flexible container design, trained personnel and the decades of experience of the BFS inventor at your disposal right away. And that always pays off!

On the right track with process development.

Take advantage of our knowledge. Even before production, you can set an important course with our experts and use pilot batches to develop the optimum BFS solution for your product.

Trials

Filtration tests for sterile filtration, and scale-up.

Laboratory tests

Microbiological tests, stability storage and testing, chemical tests, and product analysis.

Container design

Development and optimisation of the primary packaging mould, choice of plastic, and customer-specific mould design.

Your unmistakable design

We offer over 100 proven primary packaging forms from 0.04 to 2,000 ml fill volumes. These can be further perfected at your request, for example, with practical hanging devices, applicators or other features.

And if this variety is not enough, we can create a completely individual design for you and manufacture it on your behalf.

Your unmistakable design

We offer over 100 proven primary packaging forms from 0.04 to 2,000 ml fill volumes. These can be further perfected at your request, for example, with practical hanging devices, applicators or other features.

And if this variety is not enough, we can create a completely individual design for you and manufacture it on your behalf.

Trial fillings for the perfect solution.

Each product is different. Not every dosage form is optimal. We use trial fillings to determine whether your formula is suitable for BFS technology and which primary packaging is best.

Once the primary and secondary packaging has been determined, we extensively test the end products to meet both functional and aesthetic requirements.

Last but not least, our trial fillings serve as documentation for product approval.

Trial fillings for the perfect solution.

Each product is different. Not every dosage form is optimal. We use trial fillings to determine whether your formula is suitable for BFS technology and which primary packaging is best.

Once the primary and secondary packaging has been determined, we extensively test the end products to meet both functional and aesthetic requirements.

Last but not least, our trial fillings serve as documentation for product approval.

Last but not least: Quality assurance.

That is why our certified BFS manufacturing process includes several inspection systems, such as ampoule inspection machines (VIM), high voltage inspection machines (HVLD) and cosmetic inspection machines (CIM). So you and your customers can enjoy reliable quality.

Last but not least: Quality assurance.

That is why our certified BFS manufacturing process includes several inspection systems, such as ampoule inspection machines (VIM), high voltage inspection machines (HVLD) and cosmetic inspection machines (CIM). So you and your customers can enjoy reliable quality.

BFS contract manufacturing for the pharmaceutical industry.

For the pharmaceutical industry, in particular, our Blow-Fill-Seal process is a safe bet. Our Zell facility in Switzerland even offers Bio Safety Level 2 (BSL 2) certified BFS bottling, e.g. for filling vaccines - the only one in the world. In addition, we specialise in handling temperature-sensitive substances and narcotics, as well as in producing emulsions, suspensions, biologicals or the processing of highly potent APIs.

BFS up to Bio Safety Level 2

Our production is subject to the strictest protection and safety measures. This includes the strict separation of clean rooms and the use of specially trained personnel.

We have a separate facility for filling biological drugs and genetically engineered active ingredients, such as vaccines or antibodies up to BSL 2.

The core of our aseptic contract filling is the Blow-Fill-Seal technology, in which containers are blown, filled directly with pharmaceuticals and immediately hermetically sealed. This is done completely automatically to prevent any contamination.

Professional batch production

Although we only fill liquids and semi-solids, we are happy to receive your solids and produce homogeneous and stable mixtures from them. In this way, sensitive substances can be filled without loss of time and one hundred percent sterile. In addition, this often simplifies delivery and makes it safer and more cost-efficient.

Pharma Suite Service

Your own bottelpack machine is more economical for you than contract filling, but you do not have the required GMP environment, too little space or not enough manpower to operate it? Then we will be happy to set up your system in our pharma suite and manufacture with it on your behalf.

Packaging design: because looks do matter.

The right BFS primary packaging is essential for your product. Once this has been established, it is time for suitable, attractive outer packaging. As a base, we offer a wide range of blisters, sachets, folding boxes and much more. And integrate packaging and finishing economically into our contract manufacturing process.

Application examples

Our concepts are as individual as your requirements. See for yourself!

PHARMA

Single-use ampoules for eye drops

Plastics of high purity Pharmagrade and bottelpack machines 460 or 434 enable a high output (150-180 million/a) of sterile individual ampoules with 0.25-0.6 ml eye drops. Preservatives are not required for this bottling. The combination as an ampoule block is perfect for quick packaging in folding boxes. Dyed plastic granules can also be used to individualize or protect the substances.

PHARMA

Multi-dose container for eye drops

Cosmetics

Hyaluron ampoule blocks

Each bellemax hyaluronic acid dose is sterile and free of preservatives - this is guaranteed by the aseptically filled single-use ampoules made of high-purity plastic. They are manufactured as ampoule blocks on a bottelpack system bp460: 150-180 million pieces per year. The ampoule flags provide space for labelling and placement in the attractive secondary packaging. A drip-ready opening is created when the handy cap is twisted off. This makes the ampoules perfect for daily use and unbreakable if you carry them in your handbag.

Food

Bottle for electrolytes

A Suero Oral drinking bottle holds 400 millilitres, providing the perfect amount of electrolytes when it counts. Simply twist it open and drink up - or cap again if necessary. The square body fits well in hand. The polypropylene bottles are produced and sterilely filled with a bottelpack filling system bp321: 1,200 pieces per hour.

Food

Twist-and-drink bottle for fruit juice lemonades

Already a cult for more than 40 years: the Austrian brand "Dreh und Trink" which means as much as "Turn and Drink", and its unique BFS bottle with a twist-off cap helped shape the company name. Unbreakable, with recessed grips and an easy twist to open, the bottle is made especially for children's hands. It is also lightweight - both in the backpack and during resource-saving transport. It is made of brightly coloured plastic granulate, one-third of which is recycled. Our plant produces, fills and seals 50 units per minute. That is 72,000 units per day and 1,400,000 per month.

Chemistry

Pheromone container for hanging

Especially in viticulture, pheromones are valued as environmentally friendly and poison-free plant protection. Specially shaped BFS containers made of dyed LDPE with an integrated suspension device enable rapid application in the vines and the release of the attractant, which is confusing for insects. The products are produced and filled on bottelpack lines bp460: 14,000 pieces per hour.

PHARMA

Single-use ampoules for eye drops

Plastics of high purity Pharmagrade and bottelpack machines 460 or 434 enable a high output (150-180 million/a) of sterile individual ampoules with 0.25-0.6 ml eye drops. Preservatives are not required for this bottling. The combination as an ampoule block is perfect for quick packaging in folding boxes. Dyed plastic granules can also be used to individualize or protect the substances.

Cosmetics

Hyaluron ampoule blocks

Each bellemax hyaluronic acid dose is sterile and free of preservatives - this is guaranteed by the aseptically filled single-use ampoules made of high-purity plastic. They are manufactured as ampoule blocks on a bottelpack system bp460: 150-180 million pieces per year. The ampoule flags provide space for labelling and placement in the attractive secondary packaging. A drip-ready opening is created when the handy cap is twisted off. This makes the ampoules perfect for daily use and unbreakable if you carry them in your handbag.

Food

Bottle for electrolytes

A Suero Oral drinking bottle holds 400 millilitres, providing the perfect amount of electrolytes when it counts. Simply twist it open and drink up - or cap again if necessary. The square body fits well in hand. The polypropylene bottles are produced and sterilely filled with a bottelpack filling system bp321: 1,200 pieces per hour.

Food

Twist-and-drink bottle for fruit juice lemonades

Already a cult for more than 40 years: the Austrian brand "Dreh und Trink" which means as much as "Turn and Drink", and its unique BFS bottle with a twist-off cap helped shape the company name. Unbreakable, with recessed grips and an easy twist to open, the bottle is made especially for children's hands. It is also lightweight - both in the backpack and during resource-saving transport. It is made of brightly coloured plastic granulate, one-third of which is recycled. Our plant produces, fills and seals 50 units per minute. That is 72,000 units per day and 1,400,000 per month.

Chemistry

Pheromone container for hanging

Especially in viticulture, pheromones are valued as environmentally friendly and poison-free plant protection. Specially shaped BFS containers made of dyed LDPE with an integrated suspension device enable rapid application in the vines and the release of the attractant, which is confusing for insects. The products are produced and filled on bottelpack lines bp460: 14,000 pieces per hour.

Want to get in touch?

The sooner, the better!

We can only provide you with the best advice and solution if we understand your requirements. We are equipped to handle everything from BFS packaging and equipment to contract manufacturing and development to full-scale BFS production. We eagerly await your challenge!

Send us your request

Thank you for contacting us. How can we help you?

Send us your request

Thank you for contacting us. How can we help you?

The perfect solution for your application

Tell us your challenge. We will advise you in detail about the possibilities and find the optimal solution.

Send us your request

Thank you for contacting us. How can we help you?

Send us your request

Thank you for contacting us. How can we help you?