bp 321M

| Output: | Up to 9.000 pcs/h |

| Filling volume: | 0,1 – 50 ml |

| Ampoule length up to 208 mm | |

| Ophthalmic, Inhalations, Injection, technical products |

bottelpack

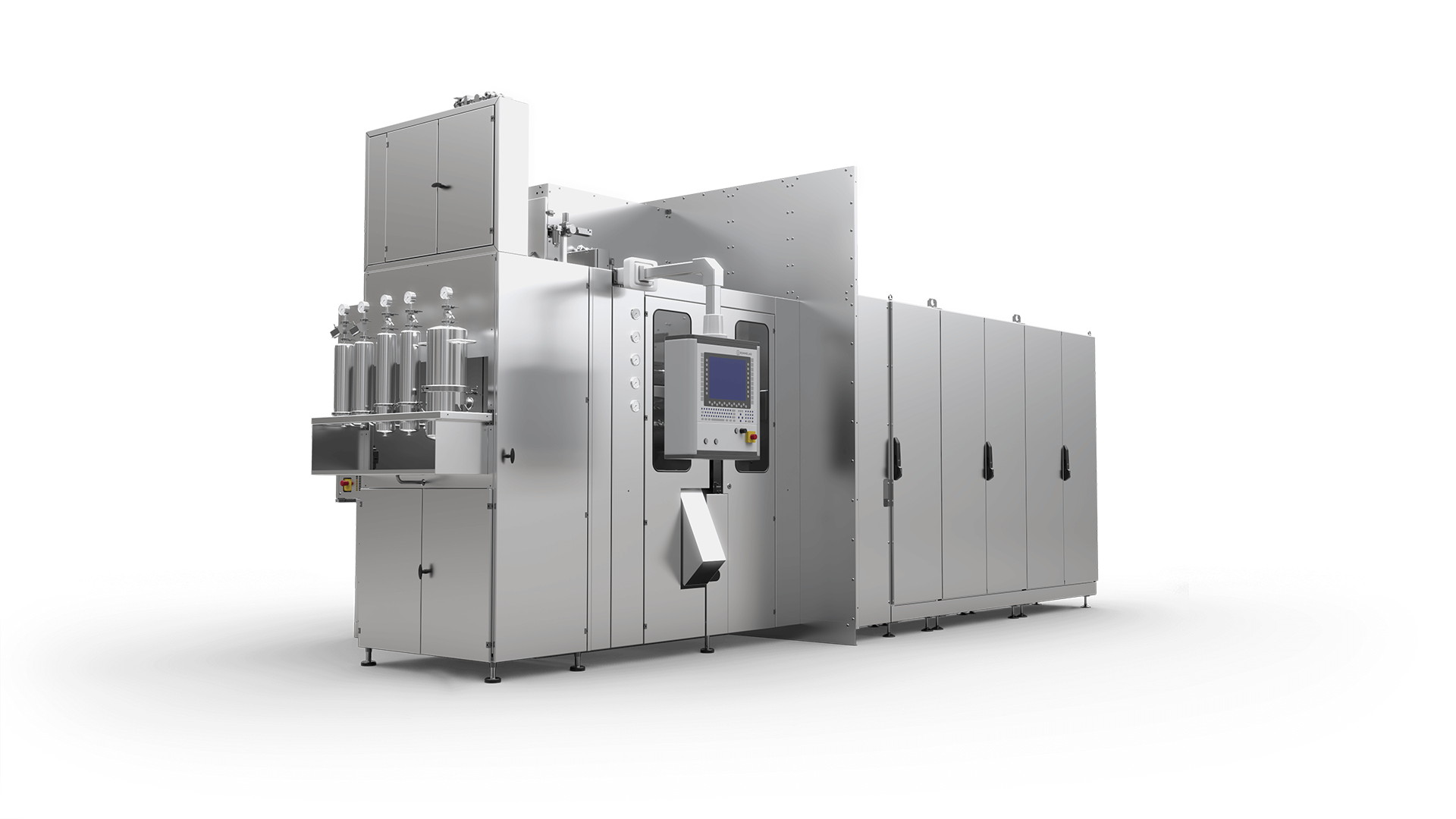

Rommelag aseptic filling machines are engineered for the pharmaceutical industry's strict demands. They form, fill, and seal BFS containers in one closed, automated step—minimizing contamination risk and cleanroom footprint while delivering up to 37,500 containers per hour at a low unit cost.

What is BFS

Benefits

Up to 37,500 containers/hour with low energy consumption and lean staffing requirements—driving competitive unit economics.

Our compact filling machines keep cleanroom requirements low, with only 7 m² of Class C cleanroom area at our 500 Series. Also, no separate washing, sterilizing, or capping trains are needed.

Closed, automated processing without human intervention significantly reduces contamination risk versus open handling or multi‑step methods.

Built with Swiss precision and German engineering since 1960, our bottelpack machines deliver high OEE year after year and are trusted by manufacturers worldwide.

Adapt filling volumes in ~15 minutes and complete format changes in <2 hours with the latest bottelpack generation, helping you stay agile in dynamic markets.

Our latest generation achieves 80% less production waste, consumes 75% less energy, and saves 420,000 liters of water annually compared to previous models.

Machine Models

Ideal for pharmaceutical products with smaller filling volumes such as ophthalmics, inhalation solutions, and injectables. Up to 37,500 ampoules/hour with a filling volume of 0.1–60 ml.

| Output: | Up to 9.000 pcs/h |

| Filling volume: | 0,1 – 50 ml |

| Ampoule length up to 208 mm | |

| Ophthalmic, Inhalations, Injection, technical products |

| Output: | Up to 18.000 pcs/h |

| Filling volume: | 0,1 – 50 ml |

| Ampoule length up to 208 mm | |

| Ophthalmic, Inhalations, Injection |

| Output: | Up to 11.250 pcs/h |

| Filling volume: | 0,1 – 30 ml |

| Closed parison and ampoule length up to 127 mm | |

| Ophthalmic, Inhalations, Injection |

| Output: | Up to 31.000 pcs/h |

| Filling volume: | 0,2 – 10 ml |

| Closed parison and ampoule length up to 92 mm | |

| Ophthalmic, Inhalations, Injection |

| Output: | Up to 33.000 pcs/h |

| Filling volume: | 0,2 – 10 ml |

| Closed parison and ampoule length up to 68 mm | |

| Ophthalmic, Inhalations, Injection |

| Output: | Up to 37.500 pcs/h |

| Filling volume: | 0,2 – 5 ml |

| Closed parison and ampoule length up to 68 mm | |

| Ophthalmic, Inhalations, Injection |

| Output: | Up to 25.000 pcs/h |

| Filling volume: | 3 – 60 ml |

| Closed parison and ampoule length up to 130 mm | |

| Ophthalmic, Inhalations, Injection |

| Output: | Up to 12.960 pcs/h |

| Filling volume: | 0,1 – 20 ml |

| Closed parison and ampoule length up to 130 mm | |

| Ophthalmic, Inhalations, Injection |

| Output: | Up to 21.600 pcs/h |

| Filling volume: | 0,1 – 20 ml |

| Closed parison and ampoule length up to 130 mm | |

| Ophthalmic, Inhalations, Injection |

For LVPs, infusion solutions, wound irrigation products, and other large-volume applications. Up to 9,200 bottles/hour; 100–1,000 ml.

| Output: | Up to 2.500 pcs/h |

| Filling volume: | 100 – 1.000 ml |

| Bottles up to 303 mm | |

| Infusions, Wound Irrigation Solutions, Injection |

| Output: | Up to 4.000 pcs/h |

| Filling volume: | 100 – 1.000 ml |

| Bottles up to 303 mm | |

| Infusions, Wound Irrigation Solutions, Injection |

| Output: | Up to 5.000 pcs/h |

| Filling volume: | 100 – 1.000 ml |

| Bottles up to 303 mm | |

| Infusions, Wound Irrigation Solutions, Injection |

| Output: | Up to 9.200 pcs/h |

| Filling volume: | 100 – 1.000 ml |

| Bottles up to 303 mm | |

| Infusions, Wound Irrigation Solutions, Injection |

RPS

Rommelag Pharma Service (RPS) accelerates and de‑risks qualification and validation for bottelpack systems—combining a proven Fast‑Track approach with modular packages and complete documentation support.

Our aseptic filling machines comply with the pharmaceutical industry's stringent requirements, including Annex 1 of the EU-GMP guidelines and those of various regulatory authorities, such as the EMA, FDA, Anvisa, and Abrasp.

Services

Our comprehensive after-sales services ensure that your bottelpack machine delivers outstanding quality and operates economically day after day.

We have the expertise you need to plan, expand, reorganize, or optimize your BFS production.

Given the extended lifecycle of our aseptic filling machines, we offer in-house modifications and upgrades to keep pace with new regulations and market demands.

Enable data insights, real-time monitoring, track your OEE, and more while ensuring the highest levels of data security.

Personal contact

Select your country to connect with the right person for your needs.